The Lighthouse has been making strides in expanding career opportunities for people who are blind in Summerville, SC. With the installation of two Okuma Computer Numerically Controlled (CNC) machines, we have expanded our precision machining capabilities and diversified job opportunities at our Summerville facility.

Roosevelt Stevenson, Production Lead, has worked for the Lighthouse for over 26 years. Bringing experience from his time operating manual machines at our Seattle facility, Roosevelt has found it relatively easy to adapt to the CNCs and has been helping to train others.

Roosevelt believes that the new machinery and expanded manufacturing capabilities will bring opportunities and independence to the visually impaired community in South Carolina.

“I think it’s a good thing because it brings people in and shows them there’s opportunity out there for us, for people who are blind,” he shares. The Summerville location has already expanded the manufacturing skill sets of three other individuals, as well.

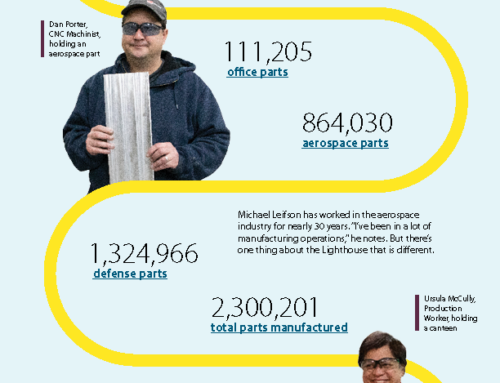

Prior to the installation of the new machines, the Summerville location has primarily manufactured MOLLE hydration systems for the military, as well as aerospace parts such as e-nuts and felt strips. The new machines are capable of producing high-precision parts, meeting the stringent requirements of the aerospace industry and allowing for production of a wider variety of aerospace parts.

All Okuma CNC machines that the Lighthouse operates have been adapted to ensure that they’re accessible for those who are blind and DeafBlind.

Summerville, SC production workers Sharon Dunbar, Dexter Gibbs, and Wanda Hartwell, alongside Production Lead Roosevelt Stevenson, stand next to an Okuma CNC machine.