Celebrating his 33-year anniversary with the Lighthouse, Mike King’s story embodies the transformative power of accessible technology.

After Mike was diagnosed with Retinitis Pigmentosa, he embarked on a journey from Wyoming to Washington, braving snowstorms, and uncertainty to pursue a career opportunity that would change his life.

Though he had no prior experience in machining, with the support of his colleagues and some training, Mike quickly adapted.

At the Lighthouse, technology isn’t just a tool, it’s a gateway to independence and advancement. Mike embraced the computer training available at the Lighthouse to learn assistive technologies like ZoomText, then JAWS, opening new avenues for learning and paving the way for career growth.

Through accessible technology, comprehensive training, and a supportive community, individuals like Mike prove that with the right tools and opportunities, the possibilities are limitless.

Mike King, CNC Machinist II, Seattle Facility

There are many types of adaptive equipment that make our machine shop accessible for people who are blind or visually impaired:

- Refreshable braille displays are electronic tools that function by raising and lowering combinations of pins. Those pins form braille dots corresponding to text on the computer screen.

- Large print screens allow text and graphics to be magnified anywhere from two times to 60 times their original size.

- Voice technology allows text to be read aloud with computer synthesized speech.

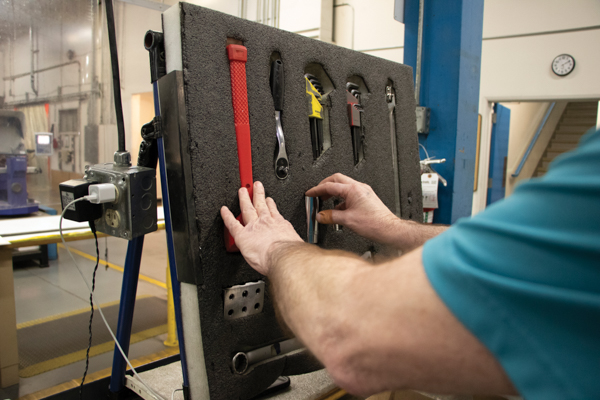

- Tactile fixturing allows machinists to identify machine controls through touch.

- Thorough organization of tools and equipment ensures that employees can locate what they need to perform their jobs safely and efficiently.

- Many other features can be implemented to fit each individual’s accessibility needs and preferences, as well.