Portrait of Ian, a light skinned man with thick rimmed glasses, salt and pepper hair and beard, who is smiling at the camera.

Accessibility at the Lighthouse

“The Innovation Lab is a mad scientist workshop for custom accessibility technology,” says Ian Stenseng. Ian is Director of Innovation and Accessibility and manager of the Lighthouse’s Accessibility Program. In addition, he is also the brains behind the Innovation Lab, where he created his newest invention – an accessible measuring device.

The lab has everything necessary to craft inventions. It is equipped with a 3-D printer, a set of tools, and an array of technological assembly pieces. But how did the Innovation Lab come to fruition?

At the Lighthouse, accessibility is key. Our Accessibility Program focuses on continuous improvement. For example, it includes focusing on accessible equipment, tools, technology, software, and physical environments.

Much of the accessible technology that is used at the Lighthouse is commercially available.

Ian explains, “accommodations range from software like screen readers and screen magnifiers, to aids and appliances like magnifying glasses or task lights. It also includes making sure physical environments are accessible.” Learn more about adaptive technology for people who are blind or DeafBlind >>

The Innovation Lab

However, the Lighthouse is the largest employer of people who are DeafBlind in the U.S. The Lighthouse is also the largest employer of people who are blind on the West Coast. Ian shares, “because of that, there are times when we have needs for accommodations in our environment where there isn’t a commercially available solution for accessibility.”

“I’ve always been a tinkerer and builder of things. It’s what I do as a hobby. So in those situations I dream something up and then build it.” Whether it’s altering existing technology, or inventing something entirely new, the Accessibility Program aims to make sure that all employees are met with the tools and technology that they need to thrive.

A case with the accessible measuring device and it’s components, with spots for a plug in speaker, refreshable braille display, and vacuum attachment.

Building an Accessible Measuring Device

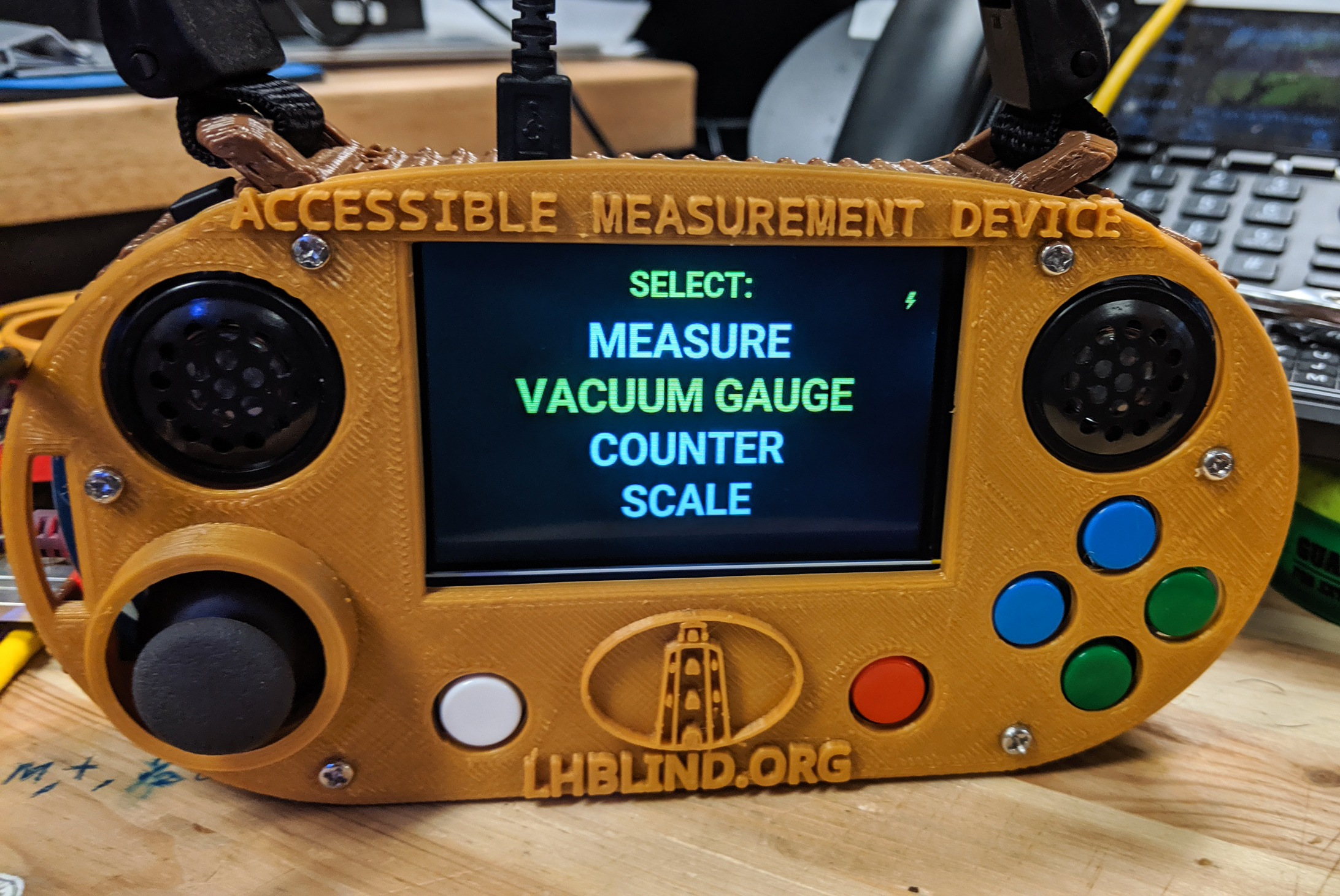

One of the recent inventions that’s emerged from the Innovation Lab is an accessible measuring device.

“This is designed to make a variety of manufacturing tools or processes accessible,” Ian explains. The device has a built-in large print, high contrast screen, and options to hook up speakers for speech output or a refreshable braille display for tactile output. It’s made to translate measurements into whatever form its user needs.

“For example, we have 5 or 6 employees who are DeafBlind who are working in aerospace production. They do a variety of manufacturing processes where they need to be able to use precise measurement tools like digital calipers. That just wasn’t a job that could be made accessible for them previously because those devices were not accessible. But with this tool, now they can be!”

Ian ensured the device would work across many different types of equipment in our machine shops. “It works with a variety of tools in our aerospace manufacturing, like our digital calipers, dial gauges and things like that.”

Making Machines Accessible

“It has a mode for parts counting. So we could hook it up to a machine that cycles like a clicker press. As a result, it will advance the count.”

“We can hook it up to digital scales if we want to know how much a particular product weighs. Or, if we want to come up with a target weight so that we can know how many of something there are, it can do that.”

“Then, there’s a little module that we can attach to it. That allows us to use it to measure sources of vacuum. That would be of use on a router table or a CNC mill. That’s where we want to make sure that we have adequate vacuum suction to hold parts in place.”

One important factor to consider when designing each new device is making it easily replicable. Ian says, “whenever I can, I try to use off the shelf commercial components. It’s all kind of cobbled together. Things are a mix of off the shelf parts and a little bit of custom software.”

“I’m creating another batch of 6 or 8 of the measuring devices. We probably have 10 or 15 of these in various areas of production throughout Lighthouse locations.”

Why the Innovation Lab is Important

“Accessibility is critical to the mission of our organization,” Ian says.

“Essentially, we can enable people to experience not just the ADA requirements of equal employment opportunities. We can go above and beyond and really enable our employees to excel.”